Factory

At KeSu, we design, program, prototype and manufacture custom parts products. Our flexible rapid prototyping development processes can provide you with different production solutiuons based on your project and demands. We are dedicated to providing manufacturing solutions for your innovation ideas and products such as impeller/gear/cavity/shaft, with one-stop services from prototyping to batch production, including a wide range of services: CNC Machining, 3D printing, Metal Sheet, Vacuum Casting, Injection Molding, Die Casting and post-processing finishes. Now, our CNC factory is trusted by customers all over the world. All of them are satisfied with our good quality, fast turn around, reasonble price and extroadinary service.

KeSu has more than 200 staff. The history of KeSu Group can trace back to 2008. KeSu is specializing in hardware machining service. Such as CNC machining service, sheet metal fabricating service and metal 3D printing (SLM/DMLS) service for the customized metal parts. KeSuRapid has considerable experience in the manufacturing of complex and difficult custom parts. Such as automotive engines, impellers, gear, cavity, shafts and embossing rollers etc produced in CNC factory.

Machining Facility Of Factory

KeSu focus on providing customers with the finest services in rapid prototyping and low-volume production. Our experienced team of engineers and technicians are dedicated to making your custom parts using the most advanced equipment and techniques. KeSu has been invested more than 100 sets of advanced equipment. Such as 4-axis and 5-axis CNC machines, CNC lathes, 5-axis Lathe-Mill Conbo Machines, CNC Swiss Type Automatic Lathe, 3D Printers, CMM, XRF-Spectrometer, Rockwell Hardness Tester and 2.5D measuring projector etc. Our factory is here to turn your ideas into reality quickly, accurately and at a great price.

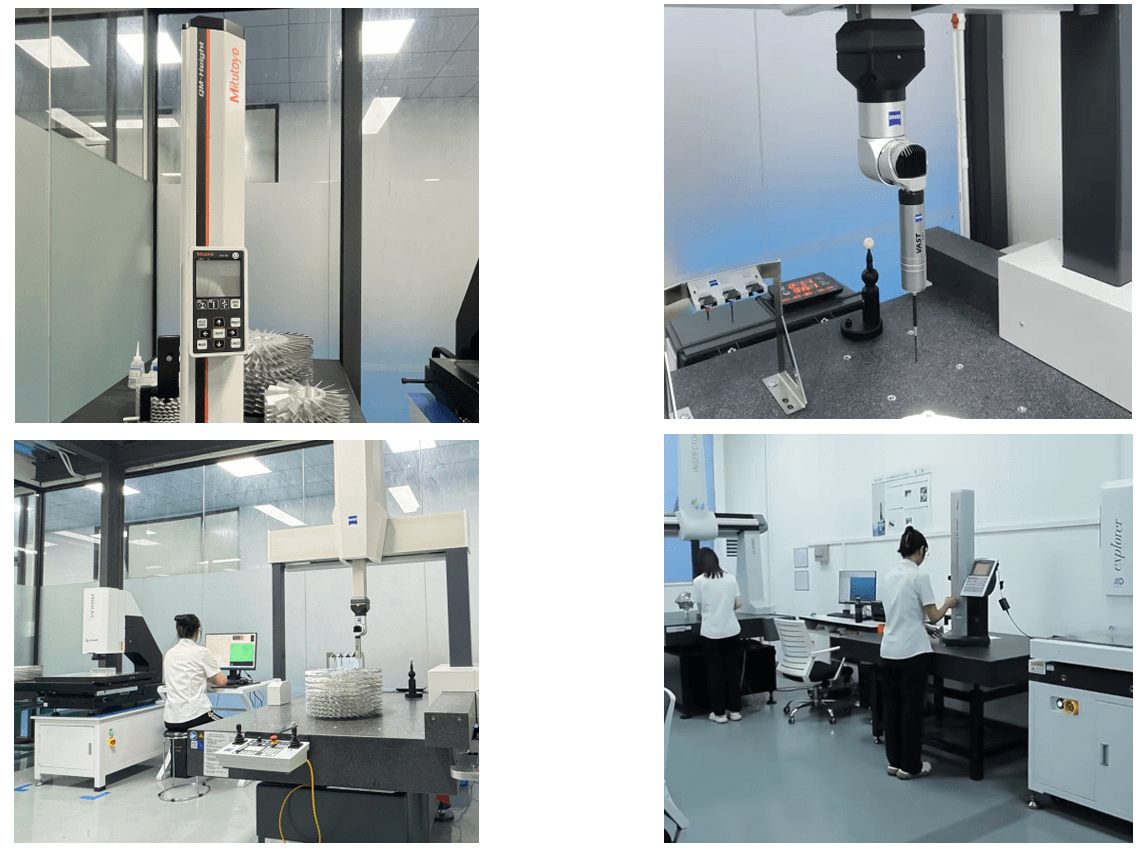

Quality Inspection Equipment Of Factory

| Device Name | Brand | Main Function |

|---|---|---|

| CONTURA Coordinate Measuring Machine | ZEISS | Precision 3D Geometric Measurement |

| X-MET8000 Handheld Spectrometer | Hitachi | Portable X-ray Fluorescence Analysis |

| HR-150A Hardness Tester | ARERP | Rockwell Hardness Testing |

| Roughness Tester | Leader | Surface Roughness Assessment |

| Coordinate Measuring Machine | Hexagon | High-Precision 3D Measurement |

| SURFTEST SJ-210 Surface Roughness Tester | Mitutoyo | Surface Roughness Measurement |

| TESA-HITE 700 Digimatic Height Gauge | TESA | Height Measurement |

| Vanta Element-S XRF Analyzer | Olympus | Rapid and accurate elemental analysis |

| HR-150A Rockwell Hardness Tester | General | Rockwell Hardness Testing |

| TS7700 Grating Spectrophotometer | 3nh | Color Measurement |

| Micrometers / Calipers / Pin Gauges / Gauge Blocks / Thread Gauges | Various | Dimensional Measurement |

Frequently Asked Questions

When should I choose CNC Machining Services?

Machined parts have the true properties of the material you select. Our CNC facotry allows you to get custom parts machined from blocks of solid plastic and metal in the same time frame.

We mill and turn low quantities of custom parts very quickly. Typical quantities are one to 200 pieces and manufacturing times are 1 to 3 business days. We offer impeller/gear/cavity/shaft developers parts machined from engineering-grade materials that are suitable for functional testing or end-use applications.

CNC machining is more expensive than plastic 3D printing, but it is the most feasible option for metal visual rapid prototypes given the high cost of metal 3D printing and metal casting.

What tolerances can KeSu Rapid factory achieve?

There is not a given set of tolerances that fits all processes and materials. In every case, the final production tolerances on your part will depend on a number of factors, including but not limited to:

- Part size, Design geometry; The number, type and size of features

- Material(s), Surface finish, Machining process

Once your order is confirmed, we will review your design and provide a design for machining review, pointing out any areas where we may not be able to achieve your desired tolerances. It's helpful if you can specify which areas in your design have critical quality tolerances that must be met and which can be slightly modified if needed to reduce time and costs involved. Here are some general production tolerance guidelines:

- General tolerances for CNC machining in metal and plastic

- Plastic injection molding tolerances

- General tolerance for metal 3D printing is +/- 0.5mm

- Shrinkage rate of +/- 0.15% is to be expected for vacuum casting

All manufacturing and technical specifications need to be clearly specified in the 2D drawings in order to be followed.

How does KeSu Rapid factory ensure the quality of my parts?

Once your order is confirmed, we will perform a full Design for Manufacturing (DFM) review to point out any issues that our engineers feel may affect the quality of your custom parts. All incoming materials are inspected and verified with a suite of testing equipment for costom parts. Final inspection reports before shipment. We have the ability to share inspection data with you in real-time so we can work together to address any quality issues you may have during low volume or trial production.

Can KeSu Rapid provide optical quality on my plastic parts?

Yes. CNC facotry combines the machining capabilities of the best combined 3-axis, 4-axis or even 5-axis CNC machining process. We also have adopted the latest diamond machining technology in higg precision machining. This is a technique called Single Point Diamond Machining (SPDM or SPDT) that can match the ability of 5-axis machining to produce a range of lens and light guides types of excellent costom parts quality in an array or freeform pattern. With the rich polishing experience, we can get amazing appearance on both inside and outside of the gear/cavity/shaft/impeller parts, providing fully support to rapid prototype development projects.

Why it is important to have a quality standard master?

The quality of the custom parts is determined by the quality of master pattern. When the requirement of a client comes to high tolerance, glossy finish or even optically clear parts, the master pattern will be manufactured with CNC machine which is characterized with high specification precision machining and high-quality surface finish.In the meantime, we also can paint parts surface for texture or satin effect to simulate the final mold texture of the product. The silicone molds will copy the details and textures from the original master, so the custom parts will come out the same as the master without any extra finish on the surface.