Trial Production

Trial Production Services

Trial Production in Engineering

In the engineering field, trial production services aim to help clients quickly create engineering prototypes and pre-production components. This not only meets the needs for design optimization, functional testing, engineering validation, and quality certification but also ensures the feasibility and quality of the product before it enters mass production. Specific services include:

- Product Verification Testing (PVT): Through short-term trial production, clients can conduct verification testing to identify and resolve issues that might affect mass production during the design phase.

- Design Optimization: Trial production allows the design team to test and refine prototypes repeatedly, thus optimizing the product design.

- Functional Testing: Ensures that the product's performance in real-world conditions meets expectations.

- Engineering Validation: Verifies whether the product design meets technical specifications and performance requirements.

- Quality Certification: Through quality control in the trial production phase, ensures the product complies with industry standards.

Role in Production Transition

- Trial production plays a crucial role: It accelerates the transition from prototype development to full-scale production:

- Quick Troubleshooting: Conducting trial production before formal production allows for identifying and solving potential manufacturing issues.

- Material and Cost Savings: Trial production helps clients find the best material usage strategies, avoiding unnecessary waste during mass production.

- Bridging Prototype and Mass Production: It serves as a link between prototyping and mass production, ensuring designs are thoroughly validated before scaling up.

Small Batch CNC Machining Services

Processing Capabilities

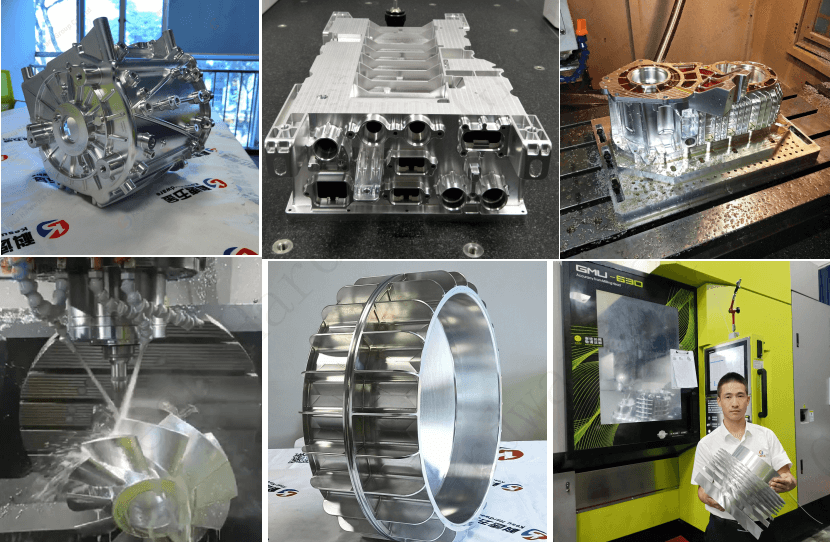

Our machining capabilities are not limited to traditional manufacturing; we have high capacity and internal CNC production capabilities, enabling us to efficiently produce high-quality, precision-machined CNC parts:

| Service Type | Description |

|---|---|

| Production-Grade Customization | Manufacture custom parts that meet production standards based on client requirements. |

| Various Metal and Custom Part Machining | Includes, but is not limited to, processing of aluminum, steel, stainless steel, and custom materials. |

| Small Batch Production | Provides full-process CNC machining services from prototyping to small batch production. |

One-Stop Service Advantages

- Professional Team: With rich knowledge and experience, we offer numerous advantages.

- Reduced Design Risk: Through professional advice and services, we minimize errors during the design phase.

- Time and Cost Efficiency: Efficient production processes and resource management shorten production cycles and reduce costs.

- Comprehensive Manufacturing Support: Offers full technical support from design to production.

With China's abundant industrial resources, we can flexibly meet various machining demands, facilitating the quick transition from rapid prototyping to mass production.

Rapid Molding Services

Service Customization

We tailor our services to meet specific client needs, offering:

- Hundreds of production-grade custom parts for reliability testing.

- On-demand production of small batch parts for final use.

Manufacturing Design Optimization (DFM)

Our engineers use DFM (Design for Manufacturing) processes to optimize manufacturing designs:

- Ensure part designs are suitable for mold making and rapid prototyping.

- Anticipate manufacturing issues, solving them in advance to reduce later engineering challenges and additional costs.

Advantages of Rapid Aluminum Molds

Aluminum molds, compared to steel molds, offer these advantages:

- Easier to machine

- Lower mold costs

- Faster production transitions

Small Batch Custom Part Production

We can meet production demands from 10 pieces to over 100,000 pieces, ensuring quality and consistency of each part, helping clients seize market opportunities.

Other Specialty Services

Complex Surface Precision Machining

We excel in precision machining of complex surfaces, with strict quality control to ensure parts meet high client standards.

Diverse Mold Options

Offering services including, but not limited to, bridge molds, prototype molds, and thin-walled molding.

Sheet Metal Processing Services

Our sheet metal processing services go beyond traditional manufacturing, focusing on: functional prototypes, assemblies, and final product production, providing custom sheet metal prototypes and production parts services.