CNC Machining for Robotic Parts

Discover how CNC machining is utilized for various robotic parts, from mechanical arms to end effectors. Understand the importance of precision machining in robotic applications and explore different components involved.

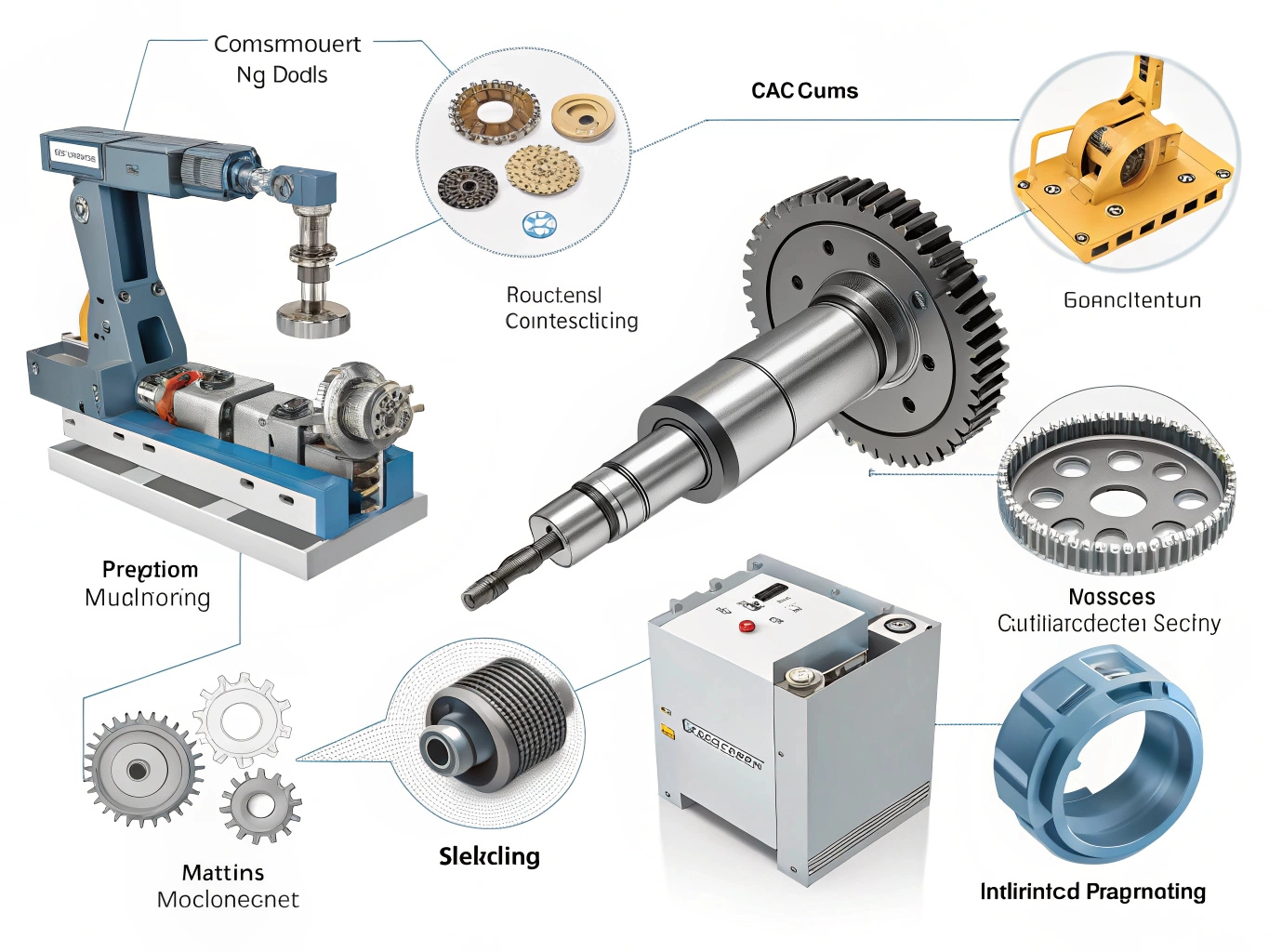

Key Robotic Parts for CNC Machining

CNC machining plays a pivotal role in the production of robotic parts. These parts require high precision and durability to ensure optimal performance in industrial applications. Below are some of the key robotic components that can be processed through CNC machining:

Mechanical Arm Components

Robot Frame and Base

Drive System Parts

End Effector Parts

Sensor and Control Components

Precision Components

Cooling and Heat Dissipation Parts

Each of these parts plays a significant role in ensuring the proper function of a robot. CNC machining is used to achieve the necessary precision and tolerances required for smooth robot movement, functionality, and performance.

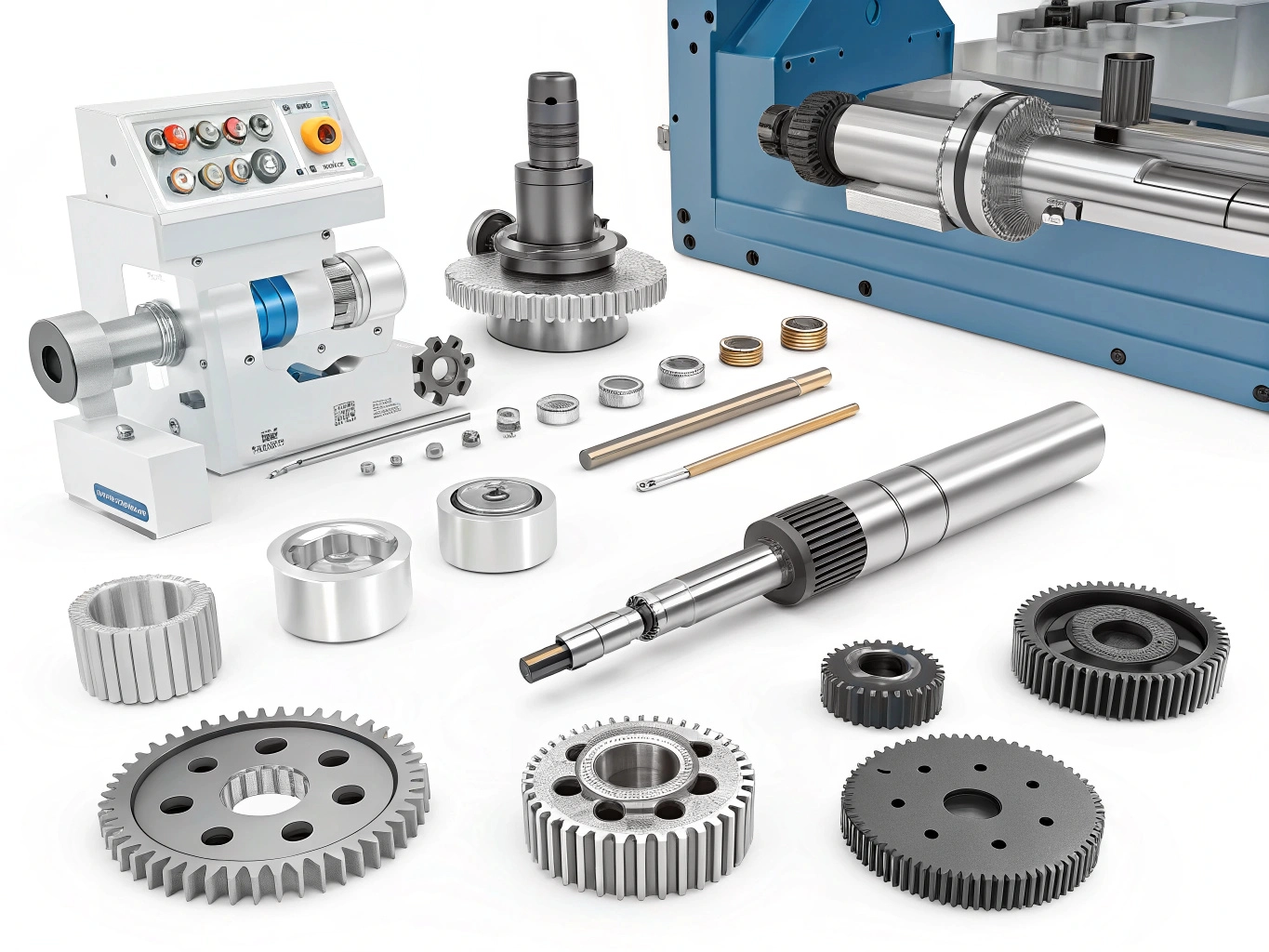

Types of Robot Components in CNC Machining

In CNC machining, robotic components are typically fabricated from various materials such as aluminum, steel, titanium, and plastic. Below is an overview of some of the common robotic parts that can be machined using CNC technology:

| Part Type | Description | Common Materials | CNC Machining Process |

|---|---|---|---|

| Mechanical Arm Components | Components like the links and joints that enable movement. | Aluminum, Steel, Titanium | Turning, Milling, Drilling |

| Robot Frame | The main structure supporting the robot's internal components. | Steel, Aluminum | Milling, Drilling, Welding |

| Drive System | Parts like gears, motors, and couplings that provide power. | Brass, Steel, Nickel | Turning, Milling, Grinding |

| End Effectors | Tools like grippers and welding torches attached to the robot's arm. | Aluminum, Steel, Brass | Precision Milling, Turning |

| Cooling Parts | Components like heat sinks used to manage temperature. | Aluminum, Copper | Milling, CNC Drilling |

The CNC machining process used for these robotic parts varies depending on the material, complexity, and function of the part. Different processes like turning, milling, and drilling are employed to meet the required tolerances and specifications.

Why CNC Machining is Crucial for Robotic Manufacturing

Robots, especially in industrial settings, require high-performance components that can withstand the rigors of continuous operation. The use of CNC machining ensures that parts are manufactured with the utmost precision, which is essential for the smooth operation of robotic systems. Below are some of the reasons why CNC machining is crucial for robotic manufacturing:

High Precision: CNC machines can achieve extremely tight tolerances, ensuring that robotic parts fit perfectly and function reliably.

Material Versatility: CNC machining can be used to process a wide range of materials, including metals, plastics, and composites, which are commonly used in robotic parts.

Efficiency: CNC machining reduces production times and enhances the efficiency of robotic manufacturing processes.

Customization: CNC machining allows for the production of custom parts that meet specific robotic design requirements.

Consistency: Once a part design is programmed into the CNC machine, it can produce identical parts in large quantities with minimal variation.

Overall, CNC machining plays a vital role in the production of robotic components by providing precise and reliable parts necessary for the functioning of industrial robots, automated systems, and robotic arms.

Kesu specializes in manufacturing high-quality robotic parts using advanced machining and rapid prototyping, focusing on precision, durability, and custom solutions. Partner with the CNC factory for reliable, cost-effective robotic parts that meet stringent industry standards, delivered in 1-14 days based on volume.

FAQ: CNC Machining for Robotic Parts

What types of materials are commonly used for CNC machining of robotic parts?

Common materials include metals like aluminum, steel, titanium, and brass, as well as plastics and composites. The material choice depends on the specific requirements of the robot part, such as weight, strength, and durability.

What are the key benefits of using CNC machining for robotic parts?

The key benefits include high precision, efficiency, versatility in materials, and the ability to produce custom, consistent parts for robotic applications.

Can CNC machining handle complex robotic parts?

Yes, CNC machines are highly capable of handling complex robotic parts with intricate geometries and tight tolerances, ensuring that each part meets the necessary specifications.

How long does it take to machine a robotic part using CNC technology?

The machining time varies depending on the complexity, size, and material of the part. However, CNC machining typically offers faster production times compared to traditional methods, especially for high-precision parts.

Is CNC machining cost-effective for small production runs of robotic parts?

Yes, CNC machining is cost-effective for small production runs due to its efficiency and ability to produce high-quality parts without the need for expensive molds or tooling.